●PRODUCTION PLANNING

OPTIMIZE PRODUCTION PLANNING FOR DEMAND AND CAPACITY.

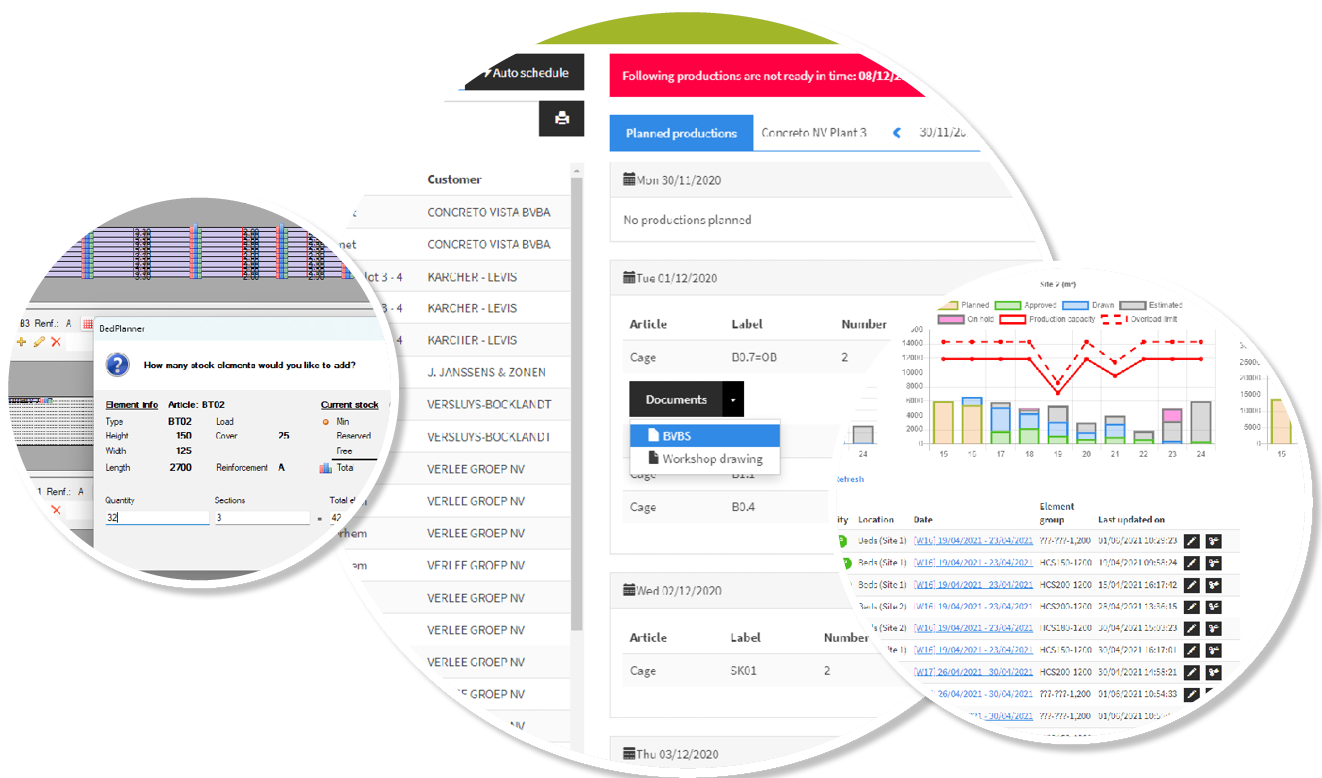

With iTs PlanDesk, you can quickly and easily optimise precast production, whatever products you make. Based on Microsoft SQL Server ®, the planning modules are a direct link between design and production. From casting beds to tables and battery moulds, you can quickly and accurately plan according to the demands of customer projects and your production capacity.

By synchronizing design data with production, you’re able to give accurate estimates to customers, optimize your labour and material usage, and deliver products on time.

Trusted by many of Europe’s

leading precast concrete producers

Planning Software

for a Range of Elements and Production Processes

PD Capacity & BedPlanner

Give accurate delivery estimates, make reservations and plan long-line production beds for flooring. Optimize bed usage based on project requirements, easily filter elements by various characteristics and create production documents at the click of a button.

PD TablePlanner - Stock

A schematic planning module to produce reinforced hollowcore slabs. Often stock elements with set dimensions, management becomes easy thanks to colour coded tables of information and minimum/maximum stock levels.

PD TablePlanner - Graphical

A graphical table planning module to produce filigree/lattice girder slabs, beams and columns, and walls. Automatically fill tables based on formwork and dimensions, with quick manual adjustment and creation of production documents.

PD MouldPlanner

Plan moulds, including batteries, with a quick and easy drag and drop graphical module. Automated filters make optimization of mould capacity simple, with mass editing tools and the creation of production documents.

PD ArticlePlanner - SteelPlanner

Coming soon

PD Calendar

A user-friendly calendar tool with drag and drop functionality. Colour coding gives you an instant visualisation of key dates and planning, with the ability to drill into detail at a click.

Who should use iTs PlanDesk Production Planner Modules?

Production Planners

Production Managers

Operations Managers

How can iTs PlanDesk

help your business?

With iTs PlanDesk, you optimize the production of a wide range of precast elements, whether stock items or made to design. Data is drawn from design and drawing modules and according to your company standards.

The ability to plan in rough detail and see clear capacity visualisations, means your salespeople can give accurate delivery estimates. Once designs are done, fine detail planning ensures that errors are minimised, and the use of raw materials and labour is optimized.

Your people will save time during the planning process, with colour coding and drag and drop functionality to make their job easier. Statistics and reports can be accessed at the click of a button. The same is true for all the key production documents, including production drawings, labels, QR codes and QC.

To complete the link with production, our planning modules can export to formats used by automated machinery, including plotters, saws and other CAM devices. It’s a seamless process, driven by a central database to minimize errors and maximize productivity.

SAVE MONEY & DELIVER TO YOUR CUSTOMERS ON TIME

By seamlessly connecting your design data with production planning you gain control over raw material costs and labour. You also reduce costly errors and wastage that can be associated with poor utilisation of production capacity.

Save time and money, increase visibility and control over key production and planning issues, and make sure you deliver the right precast products to your customers on schedule.